ZH

ZH

ZH

ZH

Flow:

280m³/hLift:

129-430mPower:

160-450kwMargin:

4.0mEfficiency:

69-77%Price:

1.6-3.8wan

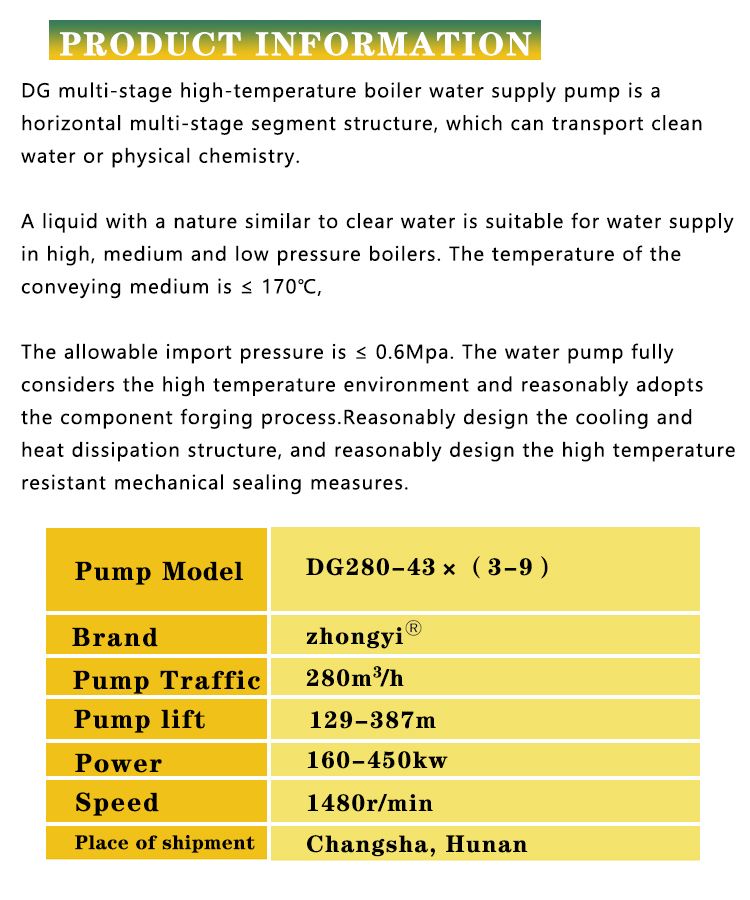

DG type multi-stage boiler feed pump is a horizontal multi-stage single-suction segment centrifugal pump, suitable for conveying water with a temperature not higher than 250°C, or non-corrosive liquids with physical and chemical properties similar to water, widely used in power plants, metallurgy, heating and other industries boiler feed water, with a maximum lift of up to 1800 meters.

The boiler feed pump shell can be axially disassembled at the axis, and the suction inlet of DG85-80×8 type pump is vertically upward, and the outlet is vertically upward, perpendicular to the axis line. From the direction of the driving end, the pump rotation is clockwise, according to user needs can also be produced counterclockwise rotation, the user can be specially put forward when ordering.

DG type multi-stage boiler feed pump parameter range and model description:

Flow Q 3.7-1350m³/h

Head H 49-1800m

Model: DG12-50×3

DG - multi-stage boiler feed pump

12 - Design point flow is 12.5m3/h

50 - Design point single-stage lift is 50m

3 - The level is 3

Our company is the production of all kinds of pumps and pump boat professional manufacturers, with its unique professional technology to occupy the market, to provide users with satisfactory and qualified products, the implementation of lifelong service is my company's service purpose. We will take the principle of capital preservation and small profit, according to IS09001 international quality management system to provide you with good service. To this end, our company hereby makes the following commitments:

1. Our company organizes production and testing according to national standards, industry standards and technical conditions stipulated in the contract, and runs strictly according to ISO9001 quality assurance system to ensure that unqualified products do not leave the factory.

2, our company to provide users with free technical advice, according to user requirements to provide design solutions, and actively cooperate with the owner and supervision. After the equipment is put into operation, professional and technical personnel will be sent to assist in the management of on-site production.

3, During the installation period, if necessary, the company can send professional and technical personnel to supervise and cooperate with the site to ensure the installation progress and quality. Our company is free to train operators for users, to the independent skilled operation, free to provide users with relevant operating procedures and rules and regulations.

4, according to the design standards and design parameters of the equipment and operation indicators for acceptance assessment, and responsible for product performance monitoring, fail to meet the standards by our company is responsible for rectification until the standard.

5, our company for the equipment warranty period: from the equipment installation and acceptance into operation and the owner issued a preliminary acceptance certificate from the date of operation 12 months, and lifelong maintenance. After the equipment is delivered through operation, during the warranty period, the quality problem of our equipment fails. After receiving your written notice, we will reply within half an hour, and we will send someone to the scene for maintenance and other after-sales services within 24 hours to ensure the normal operation of the unit. The warranty expires, our company only charges a certain cost for equipment maintenance and repair.

6, the company's products are all implemented "three guarantees", the product in the "three guarantees" period is indeed a quality problem, strict performance of the contract stipulated in the liability. And at the time of delivery to provide this batch of products certificate, product specifications.

7, our company according to the actual situation, guarantee to provide maintenance parts and according to user requirements, do a good job of maintenance services, to provide users with special tools and spare parts, this batch of products also implement the "three guarantees".

8, our company regularly or irregularly telephone return visits (or on-site inspection), listen to user opinions, exchange relevant experience, and remote network guidance, the after-sales service to do better and more perfect.

Scan